Metro Sheet Waterproofing

Metro Sheet Waterproofing

Ensuring Durability & Leak Protection

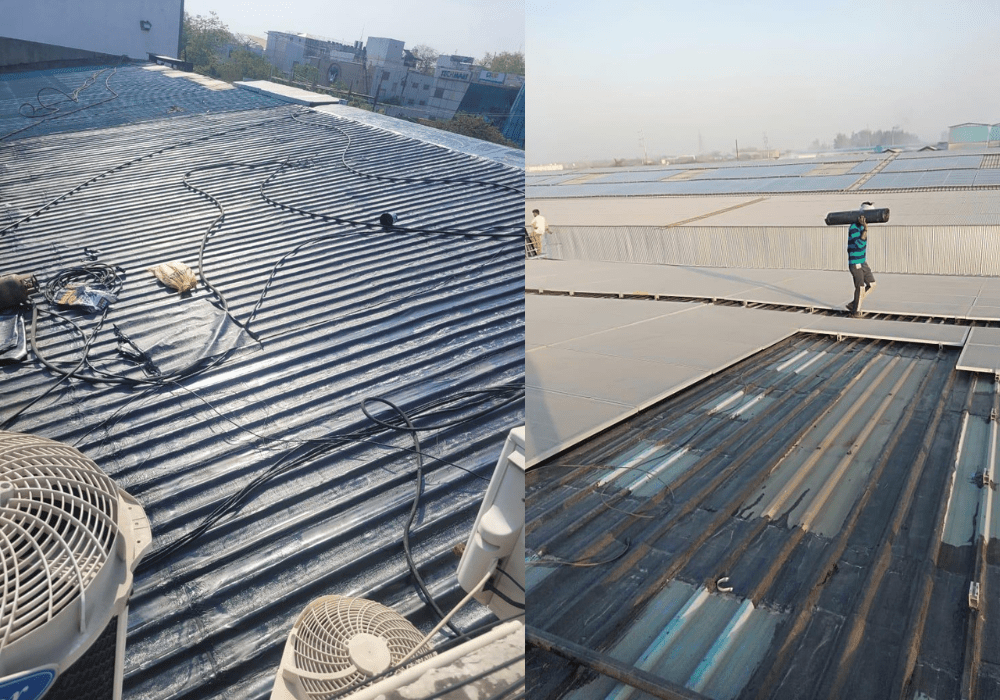

Metro structures, including roofing, panels, and underground passages, rely on metal or composite sheets that are prone to water infiltration, corrosion, and weather damage. Metro sheet waterproofing involves applying high-performance coatings, membranes, and sealants to protect against leaks, rust, and environmental wear, ensuring long-lasting structural integrity.

How Faith Infra Projects is Helping?

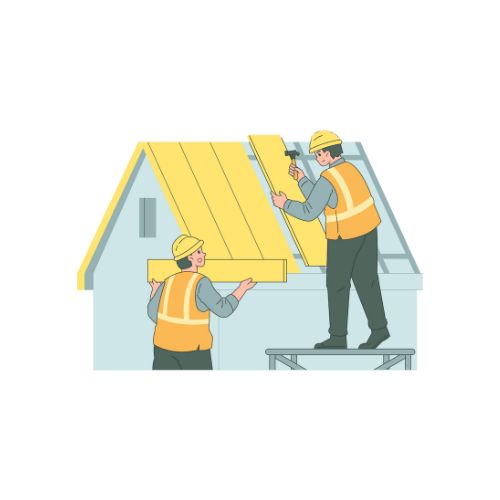

At Faith Infra Projects, we provide specialized waterproofing solutions for metro sheets using advanced coatings, polymer-based membranes, and anti-corrosion treatments. Our expert team ensures seamless application, protecting metro infrastructure from moisture, rust, and long-term deterioration.

Why Metro Sheet Waterproofing is essential?

Metro sheet waterproofing is critical for metro stations, tunnels, and transit structures, ensuring safe, weatherproof, and long-lasting performance.

✔ Prevents Leaks & Water Damage – Ensures a watertight barrier against rain and humidity.

✔ Enhances Durability – Protects metal sheets from rust, corrosion, and wear.

✔ Reduces Maintenance Costs – Minimizes frequent repairs and replacements.

✔ Improves Structural Safety – Strengthens metro infrastructure for long-term reliability.

Protect metro infrastructure with expert waterproofing solutions. Contact Faith Infra Projects today!

FAQ Section

Q1: What is Metro Sheet Waterproofing and why is it essential for infrastructure?

Metro Sheet Waterproofing is a specialized process involving the application of high-performance coatings, membranes, and sealants to protect the metal or composite sheets used in metro structures, such as station roofing, panels, and underground passages. It is essential because these sheets are highly susceptible to water infiltration, which leads to rust, corrosion, and structural deterioration, compromising long-term safety and durability.

Q2: What factors influence the Metro sheet waterproofing cost?

The final Metro sheet waterproofing cost is primarily determined by three key factors: the total area (square footage) of the sheets requiring treatment, the current condition of the metal (which dictates the necessary surface preparation and repair work), and the type of high-performance materials (coatings, membranes) selected for the barrier. We provide a thorough assessment to offer a customized and accurate estimate.

Q3: Where is this type of water proofing for Metro sheet structures typically applied?

Our specialized water proofing for Metro sheet service is applied to all critical sheet components of metro infrastructure, including station roofs, exterior cladding, platform canopies, and metal components within tunnels. The techniques used are similar to those required for large-scale commercial protection, such as treating a massive commercial building's terrace or an industrial roof, ensuring maximum weather resistance and durability in challenging environments.

Q4: How does proper Metro Sheet Waterproofing prevent corrosion and leaks?

Effective Metro Sheet Waterproofing creates a seamless, impermeable barrier that completely isolates the underlying metal from moisture, humidity, and atmospheric pollutants. This protective layer prevents water from ever reaching the metal substrate, thereby stopping the corrosion process (rust) and ensuring the structure remains leak-free, which significantly extends the service life of the metro infrastructure.

Q5. How does Metro Sheet Waterproofing protect terrace areas?

When metro sheets are used for terrace roofing, they can develop gaps or loose joints over time. A reliable Metro Sheet Waterproofing system seals all these joints, overlaps, and screw holes, preventing rainwater from entering and causing dampness or leaks in the terrace area. This ensures the terrace remains dry and damage-free even during heavy rains.

Q6. What materials are used in Metro Sheet Waterproofing?

We use high-quality elastomeric coatings, polyurethane sealants, and acrylic-based waterproof membranes. These materials create a seamless and flexible protective barrier on the surface, ensuring effective water proofing for Metro sheet installations while maintaining the roof’s aesthetic and thermal performance.

7. How long does Metro Sheet Waterproofing last?

With professional application and quality materials, Metro Sheet Waterproofing typically lasts between 5 to 10 years. Regular inspection and maintenance can extend its life further, keeping the terrace or roof fully protected from leaks and corrosion.

8. Can Metro Sheet Waterproofing be done without removing existing sheets?

Yes, in most cases, Metro Sheet Waterproofing can be applied directly over existing sheets. Advanced coating technologies allow for seamless adhesion and protection without dismantling the structure — making it a quick, efficient, and cost-effective waterproofing solution.

9. Why choose Faith Infraprojects for Metro Sheet Waterproofing services?

Faith Infraprojects offers expert assessment, premium materials, and professional application methods to ensure long-lasting protection. Our team specializes in water proofing for Metro sheet roofs, terrace areas, and industrial sheds, providing customized solutions that deliver guaranteed leak-proof results.

Our Services

💧 Looking for reliable waterproofing in Delhi NCR?

👉 Call us today for a free site inspection and get the best waterproofing services in Faridabad tailored to your needs!